This feature was originally published by The Fingerstyle Guitar Journal. We’re sharing the full interview here for our readers—spotlighting how luthier Paul McGill and engineer Ben Shaw created the Go Acoustic system that faithfully carries an acoustic guitar’s natural voice onto any stage.

What follows is the complete article from The Fingerstyle Guitar Journal, presented in full with its original structure and images, along with a featured video below.

I moved to Nashville in 2010 to attend Belmont University, where I studied audio engineering and math as a double major. While in school, I got into electronics, so I built a Princeton Reverb clone. That sparked my interest and love for the scientific side of recording and music. So, I started working in the studio maintenance department at Belmont as a technician and worked my way up through the studios to Ocean Way, Nashville. I worked there as a technician for about three years. That’s where I learned many of the electronic skills that I have while working on vintage audio gear and consoles. Pretty much everything in the studio was modded, and I was fortunate to be able to do some of the design work and circuit board layouts. On the side, I started doing custom gear design, build, restoration, and repair, all for pro audio. Then, as Paul said, Greg Morrow, who I had done some custom design and builds for, put us in contact.

When I started working with Paul, I had never worked on anything that had to run off a battery. I was used to recording consoles that were so big, hot, and power-hungry that they didn’t run the heaters in the winter because the console heated the studio. So, it was a very different set of design requirements.

Paul showed me the RMC preamps he had been using, and we started with an analysis of how they worked and what was in them. Then, we looked for a way to take the best of a couple of different designs as inspiration to create a replacement that was functionally the same but had improvements.

What were these improvements?

We were going to be using a different set of transducers, actual Piezo pickup elements that were made by Graph Tech. They sound very different than the RMC. First off, we had to make them electrically compatible. We not only had to make them sound good but better than the RMC system. We had to tune every part of the system to get where we wanted. What we ended with was almost totally different from what we started

Paul, you and Ben went through an evaluation of your pickup system. You didn’t get what you have today in a short amount of time.

In 2015, I asked Ben to make me a preamp that I could use with Graph Tech pickups. Later, in 2016, I asked Ben to make a MIDI version. At that time, Ben said he could separate all the string circuits through individual inputs and provided a more feedback-resistant system even than the RMC. It was the beginning of a game-changing experience with the product.

Between late 2016 and July of 2017, Ben improved the circuitry of the inputs to the point where we had a volume control for each string. And we had ultimate feedback control.

Later, I put the system in a guitar and asked Peter White if he would stage-test it. I wanted to see if it would survive at high concert volumes. He took it on stage one night and reported back that he had absolutely no problems. At that point, I realized we had overcome one of our big hurdles: whether our system would hold up at a high volume with bass, drums, keyboards, and the whole nine yards.

Ben, please give me your thoughts on the unique qualities of what you guys have created.

Overcoming feedback was essential, but also, most systems don’t sound great. We discovered that great guitarists were actually playing the guitar differently, and many times, it was at a subconscious level to cope with the lack of sound reinforcement capabilities. We wanted to make a pickup system that would capture all the nuances and detail of a player’s technique. The system had to do this in such a way that they didn’t have to have a different technique when they were playing acoustically or playing amplified. What they were doing subconsciously sometimes was playing the PA system, not the guitar. They heard their sound from the PA and would change their technique to get the sound they wanted. We wanted to make a system where they could play the guitar as a guitar, and the PA would amplify what the guitar and their technique were doing.

To reach our goal involved a long process of trial and error, nitpicking the circuitry and pickups. One of the first things we were able to do toward that goal was being able to have separate circuits and pickups for each string. We figured out how to run each string through a different input circuit with its own volume control. We were able to balance the strings so we could compensate for any volume discrepancies. We were able to process each of the strings individually with a bit of tone shaping before combining them. That’s where part of the feedback rejection comes from.

Ben, tell me about the Saddle-Pickup system.

Well, we were selling systems that all had Graph Tech pickups up until 2020. That was the only option we had. And we kept seeing kind of a barrier to our system was the individual saddles, that are black. And people just didn’t like the look. And some of the installers thought they were too much work to mess with. And I guess Paul and I didn’t think it was such a big deal because we do it every day.

But we saw that to get a broader acceptance of our product that it had to look like a standard bone saddle, had to sound like a standard bone saddle [acoustically], had to install and be workable like a bone saddle. I really was reluctant. I didn’t want to get into the pickup making business. I really just wanted to focus on electronics because of everything that’s involved [in pickup manufacturing].

But it was right when the COVID lockdown started. I said, “Okay, we’ll develop a pickup.” We’ve got nothing else to do. Let’s just do it. And I really was not excited about it. So, we went through a very long and often frustrating development process to get something that had all the sound we had with the [Graph Tech] individual saddles, had the individual transducers, incorporated all the previous innovation, and was one solid piece that looked like a bone saddle. You can carve it like a bone saddle, you can adjust it like a bone saddle, and it still has that sound that we have become known for.

And it still has the individual signals from each string?

Yeah, it still has all the individual signals from each string. It has all the innovation we did for feedback resistance, for clarity, everything we had become known for.

This is a good place to mention that you recently installed systems into guitars for Pat Metheny when he came to Nashville to perform. He also started his tour with one of the guitars. Two were baritone guitars with a unique tuning with the 3rd and 4th strings up an octave. Please tell me about the adjustments you made because of the wide range and tuning.

(Ben) Our product has individual circuits for each string, and each input is tuned for the frequencies of that string. So, we had to customize for the baritone tuning. We had to ask Pat what the specific tuning is and if he would vary it. When then customized the circuit on each preamp.

Thanks to Paul, he invited me to see and play the guitars with the system installed, which was very impressive.

(Paul) I appreciate you coming because I was concerned with adequate string balance with the odd tuning. I couldn’t play it, so having you around helped.

Ben wrote me one day and said we got a message from Metheny, so I wrote back and explained what we were doing. He got excited and shipped us a guitar. It was a nylon string baritone with a long scale. That Sunday, he wrote me a very positive message. His tour started the following Wednesday. I mentioned to Pat in my note that, “I fear you will want another one done for your tour.” He said, “Yes, I want another one done. If I ship it out tomorrow, can you get it to me for the show?” (Laughter). I said okay so, the guitar was at my door at 7 am the following day and on its way back to New York by 4 in the afternoon.

And you called me again and said, “There is another Metheny guitar here. Do you want to see it?”

Yeah, I had to have you check that one too.

I communicated further with Pat and his road crew, who were thrilled. Pat wrote me late in the evening after his first show while traveling and told me it was a game-changer for him. He said that he could play the guitars with more dynamics and be able to dig in more than he was used to. He said he didn’t realize how much he had been holding back.

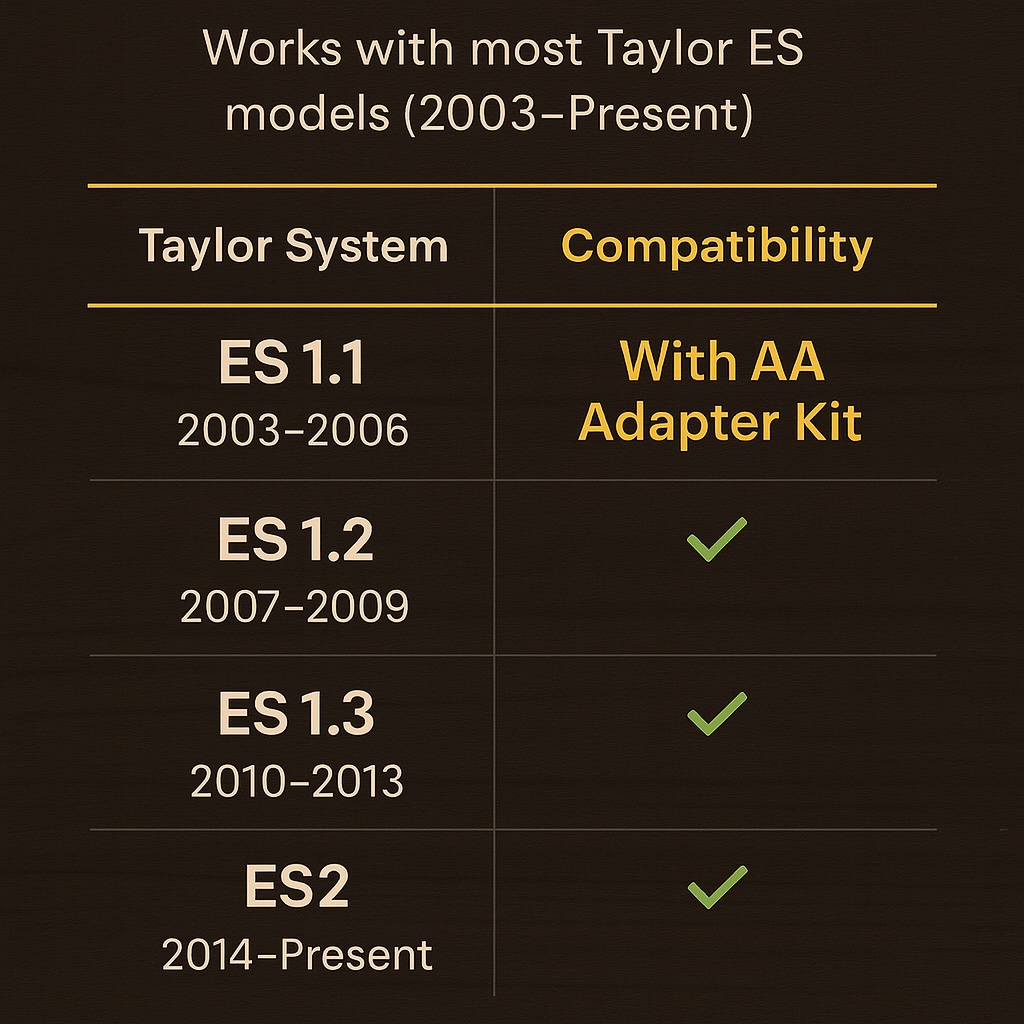

When Pat came to Nashville on October 9th, I met the crew at 8 am and retrieved a bunch of guitars. The main guitar I worked on that day was a Taylor that Pat had me install our system.

So, you guys installed the Go Acoustic system in three of Pat’s guitars, correct?

(Paul) Yes. We installed systems in his baritone classical, baritone steel-string, and his Taylor.

And Ben, you were working back and forth with Paul on all these guitars for Pat.

Yeah, because they were all baritones that had to be customized. It was a bit hectic, but we pulled it off. I visited with Pat when I delivered the guitars to the Ryman and got to go to the show.

Hearing him use your system in concert must have been a great experience.

Yeah. It was the first big show I’ve heard with our system where I was there because, for a long time, I was living in Kentucky, away from big shows. And to hear Pat Metheny use it was pretty special.

That’s starting at the top.

Yeah (Laughter).

My friend and two-time Winfield Champion Tim Thompson has three guitars with Go Acoustic systems. Another friend, Bill Colley, who plays with Kathy Mattea, recently installed a Go Acoustic system after playing Tim’s guitar. Bill emailed me to tell me how happy he was with it.

(Paul) There is a loyalty and familiarity to products that players have used for a long time. Sometimes, we have to win them over before they get the full extent of what we are doing. But, once they start playing using our system, they realize the instrument is responding like they’re not even plugged in, yet with greater volume.

Advertising and articles are great, but word of mouth from another player goes a long way.

(Paul) That’s true. We are having a lot of success with the players in South America, particularly Bolivia. I think it is because of their nylon string players’ overall skill level. They play with speed and dynamics, so they need clarity and definition. Once our product became known to players there, we suddenly had several well-known acts using Go Acoustic systems.

We’ve been working with a guitar maker or two down there, putting in system after system in guitars for known players in South America, and it’s continuing to grow.

I want people to know that the Go Acoustic system works equally well in steel-string and nylon-string guitars.

(Ben) The systems work equally well for steel string and nylon string. There is some tuning ability built into the circuit that you can do when you install it, allowing you to voice the system a little bit more for steel or nylon string.

(Paul) The system is faithful to the instrument’s sound. I can use it in one of my resonators or classical guitars, and the system remains true to the instrument’s character.

In my opinion, the goal of a pickup should be to reproduce the sound of the instrument, not to alter its character. That is a real plus of what you guys have accomplished.

(Paul) Well, thank you.

Many people confuse what we do with what they know. That’s because we’re not well-known to most people yet. When they find out we use a Saddle-Pickup, they immediately compare it to a pickup saddle they know of. But the difference between our system and others is that our pickup sends six individual signals.

I want to talk about the microphone and the ability to blend it with the bridge pickup. Ben, will you address this?

Yeah. We got into the microphone when we talked with a guitar manufacturer in early 2020 that said they had to have some soundboard transducer for percussive playing. We went with a microphone because we couldn’t get a top-sensor sound that we liked that blended with our pickup. We were aware of the limitations of internal microphones in guitars, so I designed the circuit to avoid that body compression sound. People immediately liked it, and they weren’t using it for percussion at all. They were just blending it with the pickup. We haven’t changed that design since the beginning, except we’ve made it louder relative to the piezo pickup. People love it, and it doesn’t have as much feedback sensitivity as other onboard mics.

I have the Go Acoustic in one of my nylon string guitars. The ability to blend the microphone with the piezo makes the guitar sound more like the guitar.

(Ben) It’s important to note that our Saddle-Pickup does 90% of the work. The microphone adds some resonance, some body and air. It’s that sound that everyone associates with a studio condenser microphone.

The weakness of other pickup systems is that they are asking their microphone to do more than a microphone can. So, we figured out the unique qualities a microphone can add to the sound, and we’re only asking it to add that.

If the guitar can produce it, our system can reproduce it. That is what makes the Go Acoustic system so successful.

https://www.goacousticaudio.com/

https://www.youtube.com/watch?v=JisAvqZQMPc

https://www.youtube.com/watch?v=e4-mRzYV-xo